Home > Product > Pre-fold and Crash Lock Bottom Folder Gluer

Automatic Folder Gluer

Automatic folder gluer Manufacturing method of fully automatic folder gluer The utility model relates to a paper box processing equipment, more specifically, it relates to a fully automatic folder gluer . Here is the manufacturing method of fully automatic folder gluer. Manufacturing method of…

Product Details

Automatic folder gluer

Manufacturing method of fully automatic folder gluer

The utility model relates to a paper box processing equipment, more specifically, it relates to a fully automatic folder gluer.Here is the manufacturing method of fully automatic folder gluer.

Manufacturing method of fully automatic folder gluer:background technique

During the working process of the general automatic folder gluer, due to the different shapes of the products, the various parts of the guiding device are not closely matched, which causes the product to be unstable in the conveying process. The working mode of the guiding device is single. There are not enough types of products to be delivered.

Manufacturing method of fully automatic folder gluer:technology realization elements

In view of the shortcomings of the prior art, the purpose of the present invention is to provide a fully automatic folder gluer with close cooperation between the various components of the guiding device and diversified working modes of the guiding device.

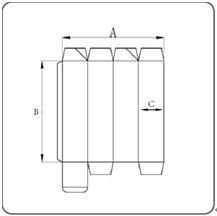

In order to achieve the above objective, the present invention provides the following technical solutions: a fully automatic folder gluer, including a machine body.The machine body includes a transmission part, a guide part and a worktable, and the guide part includes a first guide device and a first guide device symmetrical about the transmission part. Two guiding devices. The first guiding device includes an adjusting belt, a positioning member, a guiding member and a reversing member. The first guiding device is provided with a fixed cylinder in the direction from the first guiding device to the second guiding device, and the adjusting belt includes a guiding belt. The guide belt includes a first guide surface and a second guide surface. The second guide surface is in contact with the fixed cylinder. The reversing member is placed on the worktable. The first reversing cylinder and the third reversing cylinder are arranged in the transmission direction of the conveying part in sequence, and the guide belt is in sequence with the first reversing cylinder, the second reversing cylinder and the third reversing cylinder. The first guide surface conflicts with the second reversing cylinder, and the second guide surface conflicts with the first reversing cylinder and the third reversing cylinder. The positioning member includes a plurality of positioning cylinders, and the plurality of positioning cylinders are evenly placed on the worktable. A number of positioning cylinders are located on the same straight line as the first and third reversing cylinders. The guide includes a guide frame, a number of guide discs movably connected to the guide frame, and a number of guide cones. The guide frame is placed in the same line as the fixed cylinder. The guide frame is connected to the machine body on the plane of the shaft, two guide plates are arranged between the fixed cylinder and the first reversing cylinder, and the two guide plates both collide with the second guide surface.

Further, the guide plate and the guide cone are evenly placed between two adjacent positioning cylinders.

Further, the guide frame includes a connecting rod, a supporting rod, a movable part, and an adjusting part. The adjusting part is connected with the supporting rod. The adjusting part is provided with a bar-shaped through hole. Bolt threaded connection, the bolt is movably connected with the locking block, the bolt passes through the bar-shaped through hole and the sliding block and the locking block collide with the adjusting member, the sliding block is provided with a connecting hole, the connecting rod passes through the connecting hole, and the connecting hole is connected to the bolt. It is vertical and the connecting rod is in contact with the bolt, and one end of the connecting rod is movably connected with the guide cone or the guide plate.

The beneficial effects of the utility model are: the first guiding device and the second guiding device that are symmetrical about the transmission part work synchronously, ensuring the high stability and high efficiency of the guiding part. To ensure the next step of the process, and the guide belt from the fixed cylinder to the reversing part, through the setting of the reversing part and two guide plates, the first guide surface gradually changes from being parallel to the worktable to being perpendicular to the worktable. The first guide surface is parallel to the second guide surface. The first guide surface of the part of the guide belt that extends backward from the reversing member tends to be parallel to the worktable. The surface is turned and changed, and the product completes the reversing step under the cooperation of the first guide surface and the conveying part, adjusting the two guide plates between the fixed cylinder and the first reversing cylinder can adjust the angle of the guide belt.In order to be suitable for the conveying of different products, several positioning cylinders position the adjusting belt so that the adjusting belt is not easy to leave the working position, thereby ensuring the stability of the transmission, sliding the slider up and down to adjust the height of the guide plate or the guide cone, and the sliding connection Rod, you can adjust the distance between the guide plate or the guide cone and the adjustment belt, turn the slider. You can adjust the distance between the guide plate or the guide cone, and at the same time, you can also adjust the guide plate or the guide cone to adjust the angle. After the angle and distance, screw the bolt to make the bolt conflict with the connecting rod, and then tighten the locking block to fix the slider. This realizes the diversified work of the guide part and facilitates the work of more different types of products.

These is manufacturing method of fully automatic folder gluer.

Previous: Folding And Gluing Machine

Next: Mesin Folder Gluer

Hot Tags: automatic folder gluer, manufacturers, suppliers, customized, discount, made in China, Pre Fold Folder Gluer, Straight Line Folder Gluer Equipment, Automatic crash lock bottom folder gluer, Small Box Folder Gluer, Straight Line Folder Gluer Machine, High Speed Pre Fold Folder Gluer