Home > Product > Crash Lock Bottom Folder Gluer

Folder and Gluer Machine

Folder Gluer Machine The Components of Folder and Gluer Machine 1.Feed section. It is composed of paper feeding belt, main front gauge, auxiliary front gauge, side baffle, paper feeding speed, belt roller and paper stack back baffle. (1)Feed belt. The tension of the paper feeding belt should be…

Product Details

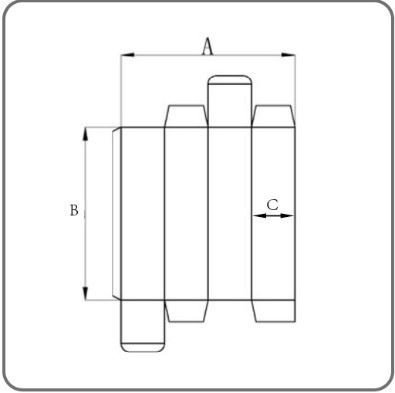

Folder and Gluer Machine

The Components of Folder and Gluer Machine

1.Feed section. The folder and gluer machine’s feed section is composed of paper feeding belt, main front gauge, auxiliary front gauge, side baffle, paper feeding speed, belt roller and paper stack back baffle.

(1)Feed belt. The tension of the paper feeding belt should be even and equal, and tight enough to prevent the belt from sliding on the drive shaft. According to the carton size, use as many belts as possible.

(2)Main front gauge.The main front gauge must be on a certain paper feeding belt, and then the position of the main front gauge should be determined according to the cardboard box. The following principles should be observed: the main front gauge should be placed between the first and the third crease as far as possible; As far as possible to make the main front gauge automatically close to the middle of the cardboard box; The main front gauge should be placed opposite the longest front board and the widest board as far as possible. The height of the main front gauge should be adjusted according to the thickness of the paperboard to ensure that the paperboard can pass freely, but there should be no gap. The electronic double sheet detection system is used to control the appearance of double sheet.

(3) Vice front gauge. The function of the auxiliary front gauge is to further support the paper stack at the front to prevent the paper stack from falling down due to the gap between the side baffles. The height of the auxiliary front gauge is generally 3 times of the thickness of the paperboard.

(4) Side baffle. When adjusting the side baffle, it should be avoided that the folder and gluer machine’s paperboard is too crowded between the two side baffles. Generally, a gap of 1-2mm should be left.

(5) Feed speed. The paper feeding speed of the folder and gluer machine is adjusted by the CVT. Pay attention not to use the CVT when the folder and gluer machine is stopped.

(6) Belt roller. The pressure roller of the conveyor belt can make the paperboard align against the side baffle to ensure the correct position of the side of the paperboard.

(7) The back baffle of the stack. The function of the stack back baffle is to tilt the stack slightly for paper feeding.

Previous: automatic folder gluer machine

Next: folding and gluing machine

Hot Tags: Folder and Gluer Machine, manufacturers, suppliers, customized, discount, made in China, High Speed Prefold And Crash Lock Bottom Folder Gluer, High Speed Prefold And Crash Bottom Lock Folder Gluer, Folder Gluer For Cup Sleeves, Straight Line Folder Gluer Equipment, Corrugated Box Folder Gluer, High Speed Pre-Fold Folder Gluer