Home > Product > Pre-fold and Crash Lock Bottom Folder Gluer

Automatic Paper Boxes Bottom Lock Folding Gluing Machine

The whole machine operation is completed by the servo pneumatic, PLC programming control, smooth operation.

Product Details

ZH-M1650-PC Automatic Folder Gluer

1. Characteristics:

The whole machine operation is completed by the servo pneumatic, PLC programming control, smooth operation.Multi-function box system mode to build Angle can be completed, around the center Angle and Angle.Quadrilateral pressure bubble structure with double guide rail and the adjusting screw, is accurate, convenient debugging with high efficiency.Take off a box adopts vacuum pneumatic demoulding structure, simple operation, convenient debugging.

2. Main technical parameter:

Model | ZH-M1650-PC |

Suitable material | Card board 210-850gsm,E/C/B/AB flute corrugated board |

Max method | Automatic continuous feeding |

Max mechanical speed | 350m/min |

Overall dimension | 19600*2500*1650mm |

Weight | 13.5T |

Power consumption | 23.6KW,380V,50HZ |

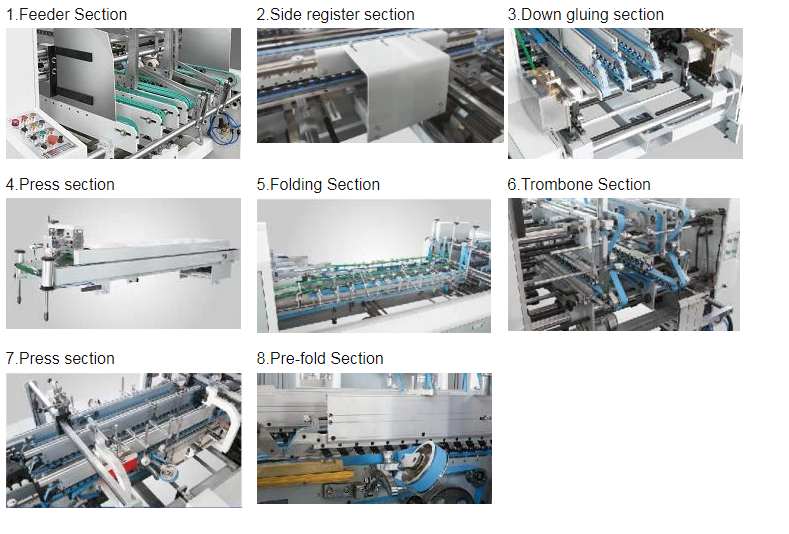

3.Machine configuration

Main motor | GPG Taiwan |

PLC | Siemens |

Inverter | Siemens |

Touch screen | Siemens |

Timing belt and pulley | Optibelt german |

Bearing | NSK |

Main axis | Taiwan chrome plated steel bar |

Wall thickness | 20mm tempered |

Plain belt | NITTA Japan |

Low voltage apparatus | Schneider |

Fasten bolts | Level 12.9 Taiwan |

Air cylinder | AIR TAC Taiwan |

Button | Schneider |

4.Standard & Optional configuration list

Configuration | Units | Standard | Optional | |

1 | Feeder section | √ | ||

2 | Paper Alignment Section | √ | ||

3 | Pre-fold Section | √ | ||

4 | Crash lock bottom section | √ | ||

5 | Upper paste barrel equipment | √ | ||

6 | Down pasting equipment | √ | ||

7 | Gluing system | √ | ||

8 | Grinder device | √ | ||

9 | Plasma treatment system | √ | ||

10 | Folding and closing section | √ | ||

11 | Trombone section | √ | ||

12 | Air compressor | √ | ||

13 | 4-6 corner | √ |

5.Feature:

The machine is running steady with strengthened singleside driving system, and it is also easy for maintenance.

The motor is controlled by a transducer (inverter) which is available for automatic timing. It is power saved and it helps to work stably.

Paper is feed by several thick belts under the help of vibration motor. Feeding is continuous, exact and automatic with this system.

Grinders are provided in both sides of machine, to make gluing more stable and firm.

An infrared photoelectric control system is in this machine. Pressing unit and counter will work synchronously with the feeding speed. Machine will slow down and stop running when no sheet there. And it’s also able to reduce waste.

Small box like out-put size at 35mm is able to be done after the special design.

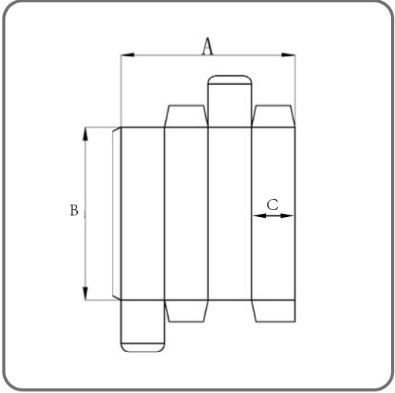

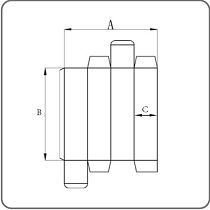

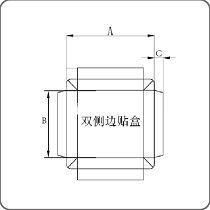

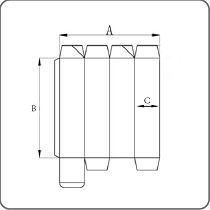

| Straight line box | Double sides box | Crash-lock bottom box | |

A | MAX | 1700 | 1650 | 1600 |

MIN | 300 | 300 | 300 | |

B | MAX | 1200 | 1200 | 1200 |

MIN | 100 | 150 | 100 | |

C | MAX | 500 | 250 | 400 |

MIN | 30 | 20 | 50 | |

Exhibition in guangzhou and beijing

Our team

Previous: Cardboard Box Bottom Lock and Prefold Gluer Folde

Next: Prefold Crash Lock Bottom Box Folder Gluer

Hot Tags: automatic paper boxes bottom lock folding gluing machine, manufacturers, suppliers, customized, discount, made in China, Corrugated Box Folder Gluer, 4 6 Corner Automatic Folder Gluer Machine, Straight Line Box Making Machine, Crash Lock Bottom Carton Box Folder Gluer Machine, Automatic 4 6 Corner Box Folding Gluing Machine, Prefold And Crash Bottom Lock Universal Folder Gluer

Inquiry: