Home > Product > Straight-Line Folder Gluer

Folder Gluer Machine

Folder Gluer Machine 1. INTRODUCTION : ZH-MC Series Automatic Folder Gluer is a multi function model, suitable for card board, EB flute corrugated board, can do two fold. This model has corectiondevice and bottom lock device. Can make electrical adjusting. Has UV destroying device…

Product Details

Folder Gluer Machine

1. INTRODUCTION:

Folder Gluer Machine is a multi function model.The folder gluer machine is suitable for card board, EB flute corrugated board. This model has corectiondevice.Can select bottom lock device. Can make electrical adjusting. Has UV destroying device and dust removing device for better gluing effect.

Functions: auto feeding, auto correction, creasing, auto alignment, pneumatic box pressing.

2.CHARACTERS:

1.Driving by synchronous belt,ensure smooth and accurate running.

2.Inverter driving,stable and power saving.

3.The folder gluer machine uses electric adjust.The folder gluer machine is easy to operate.

4.Automatic continuous feeding,use multiple belt with vibrating motor,(for higher configuration use drilled suction belt),to keep the feeding stable.

5.Automatic counting and kicking,quantity can preset.

6.Conveyer pressure adjustable according to the box to ensure best quality.

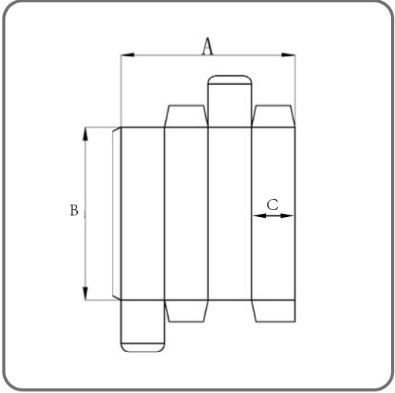

Straight line box | ||||||

ZH-M1050-S | ZH-M1250-S | ZH-M1450-S | ZH-M1650-S | ZH-M1850-S | ||

A | MAX | 1100 | 1300 | 1500 | 1700 | 1900 |

MIN | 180 | 180 | 300 | 300 | 300 | |

B | MAX | 1100 | 1100 | 1200 | 1200 | 1200 |

MIN | 70 | 70 | 80 | 100 | 100 | |

C | MAX | 400 | 450 | 500 | 500 | 500 |

MIN | 15 | 15 | 20 | 30 | 30 | |

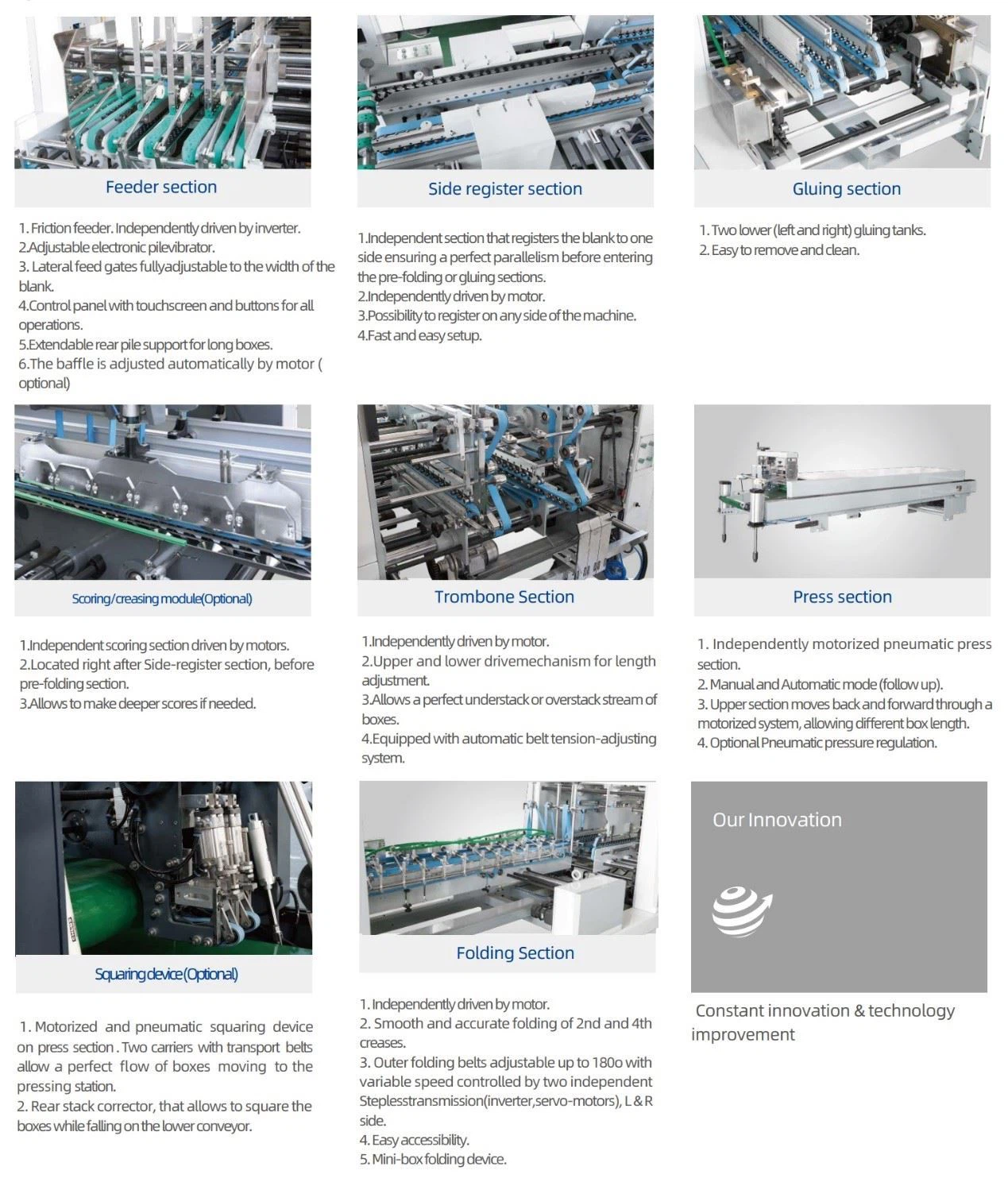

3.Features:

4.Samples:

5. Main technical parameter:

Model | ZH-M1250-S | ZH-M1250-S | ZH-M1450-S | ZH-M1650-S | ZH-M1850-S |

Suitable material | Card board 210gsm-850gsm,N/E/FB flute cormugated board | Card board 210-850gsm,E/C/B/AB flute corrugated board | Card board 210-850gsm,E/C/B/AB flute corrugated board | Card board 210-850gsm,E/C/B/AB flute corrugated board | Card board 210-850gsm,E/C/B/AB flute corrugated board |

Max method | Automatic continuous feeding | Automatic continuous feeding | Automatic continuous feeding | Automatic continuous feeding | Automatic continuous feeding |

Max mechanical speed | 350m/min | 350m/min | 350m/min | 350m/min | 350m/min |

Overall dimension | 15000*1900*1650mm | 15000*2100*1650mm | 15600*2300*1650mm | 15600*2500*1650mm | 15600*2700*1650mm |

Weight | 8.5T | 9.5T | 10.5T | 11.5T | 12.5T |

Power consumption | 14KW,380V,50HZ | 14KW,380V,50HZ | 19.2KW,380V,50HZ | 19.2KW,380V,50HZ | 19.2KW,380V,50HZ |

6.Machine configuration

Main motor | GPG Taiwan |

PLC | Siemens |

Inverte | Siemens |

Touch screen | Siemens |

Timing belt and pulley | Optibelt german |

Bearing | NSK |

Main axis | Taiwan chrome plated steel bar |

Wall thickness | 20mm tempered |

Plain belt | NITTA Japan |

Overall dimension | Schneider |

Low voltage apparatus | Level 12.9 Taiwan |

Fasten bolts | AIR TAC Taiwan |

Air cylinder | Schneider |

7.Standard & Optional configuration list

Configuration | Units | Standard | Optional | |

1 | Feeder section | √ | ||

2 | Paper Alignment Section | √ | ||

3 | Pre-fold Section | √ | ||

4 | Crash lock bottom section | √ | ||

5 | Upper paste barrel equipment | √ | ||

6 | Down pasting equipment | √ | ||

7 | Gluing system | √ | ||

8 | Grinder device | √ | ||

9 | Plasma treatment system | √ | ||

10 | Folding and closing section | √ | ||

11 | Trombone section | √ | ||

12 | Air compressor | √ | ||

13 | 4-6 corner | √ |

8.Exhibition:

9.Workshop

10.Our team

11.certificate

12. postscript

Optional: 4-6 corner part (with KEQI brand gluing system)

4-6 corner part (with HHS brand gluing system)

Plasma 2 guns

Delivery : 40 days after receive deposit.

Packing : Film packing and loaded in 1*40GP and 1*20GP, if need wooden packaging need add 1600$.

Payment terms: 1) T/T.30% deposit in advance, and 70% balance before shipped.

Warranty period:12 months

Buyer need to pay travel expenses(ticket),hotel accommodation,food .

Supplier will send one engineer to customer’s factory for installation and training ,100$ salary every day.

For the video send by whatsapp.

Most of the folder gluer machines on major network platforms are manufactured in Guangdong and Wenzhou, Zhejiang, accounting for more than 89% of the total number of plastic box machine manufacturers. Recently, Wenzhou Packaging Federation is busy discussing the establishment of a set of conventional mechanisms to make the expert committee set up by the Federation better serve the member enterprises, so as to promote Wenzhou packaging to a higher level with design forces, and realize the vision of Wenzhou from a “big Packaging City” to a “strong packaging city” as soon as possible.

Wenzhou has strong packaging strength. It is understood that Wenzhou packaging industry has formed a complete packaging industry system including packaging machinery, packaging materials, packaging and printing, plastic packaging and paper product packaging.Several packaging industry blocks with obvious agglomeration characteristics have been formed in the whole city.Packaging machinery is mainly concentrated in Ruian City, known as “China Packaging Machinery City”.Packaging printing is mainly concentrated in Cangnan County, Longgang Town and Lucheng District, is known as “China Printing City” . Plastic packaging is mainly concentrated in Pingyang County, known as the “plastic capital of China”. In addition, Wenzhou Packaging also has two golden business cards, namely “Zhejiang Special Packaging Industry Base” and “China Packaging City”.

Previous: Folding Gluing Machine

Next: Straight Line Folder Gluer

Hot Tags: folder gluer machine, manufacturers, suppliers, customized, discount, made in China, Prefold And Crash Bottom Lock Gluer Folder Machine, 4 6 Corner Automatic Carton Gluer Machine, Auto Prefold And Crash Bottom Lock Box Gluer Machine, Automatic Straight Line Folder Gluer, 4 And 6 Corner Automatic Folder Gluer Machine, Crash Lock Bottom Folder Gluer